MIL-DTL-11891G(AT)

element of his inspection system, rejected inspection lots may be resubmitted for acceptance if the

contractor performs 100 percent inspection on the lot for those characteristics which were

defective and resulted in rejection of the lot and removes all defective units or obtains procuring

activity approval to resample the lot due to the insignificance of the defects. Resubmitted lots

shall be kept separate from new lots and shall be clearly identified as resubmitted lots. Blemishes

on rubber components which have not been listed in table VI and are primarily appearance or

cosmetic conditions (poor markings, pitting of molds, minor surface contamination) should be

resolved by manufacturers as these conditions arise.

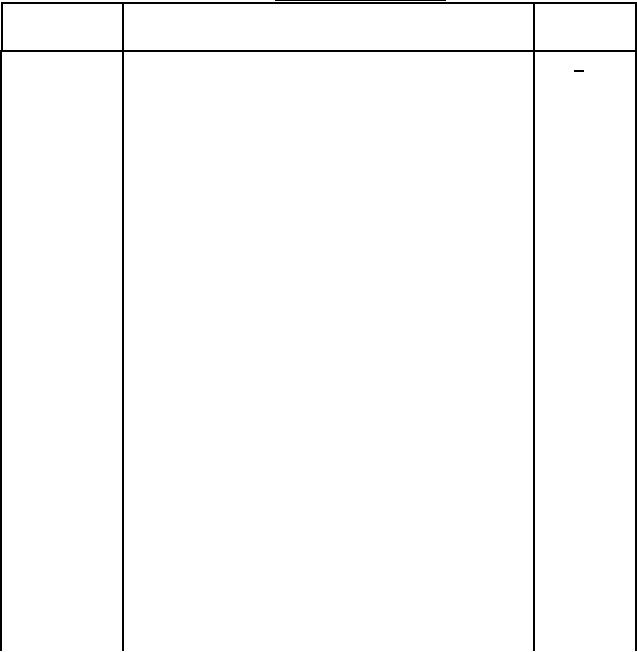

TABLE VI. Classification of defects.

Method of

Classification

Defect

inspection

SIE 1/

Blisters

A void or hole in article which causes protrusion on

surface when hot, may not show on surface when cold

- unacceptable in bushings. Allowable tolerance 1/16

inch max length/depth on pads and wheel-side rubber.

Same as backflow or back-flash. Distortion at the

mold line in the form of wrinkles, folds, tears.

Back-rinding

Unacceptable on bushings. Allowable tolerance 1/16

SIE

inch deep, 1/16 inch wide, 1/2 inch length along the

mold line.

Cracks

Failure of rubber stock to knit together properly. It

Visual

may be found in any part of the rubber surface and also

at the rubber base next to the metal.

SIE

Rubber missing due to chipping, usually during

Chipped

removal from mold or during trimming. Unacceptable

on bushings. Allowable tolerance 1/8 inch max in

depth/ length, provided there is no cutting beyond this

dimension.

Visual

A slit, nick, or gash caused primarily by trimming

Cuts/Tears

of vulcanized components. Tear may be caused during

removal of items from molds.

Visual

A crease or pleat, usually appears as overlap of rubber

Folds

on itself with a relatively weak cohesion.

Visual

Any extraneous matter such as wood, paper, metal,

Foreign

dirt, etc. penetrating past the rubber surface.

materials

SIE

Thick spew-out rubber during moldings that results

Wide flash

in dimensional noncompliance of the vulcanized

component.

28

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business