MIL-DTL-11891G(AT)

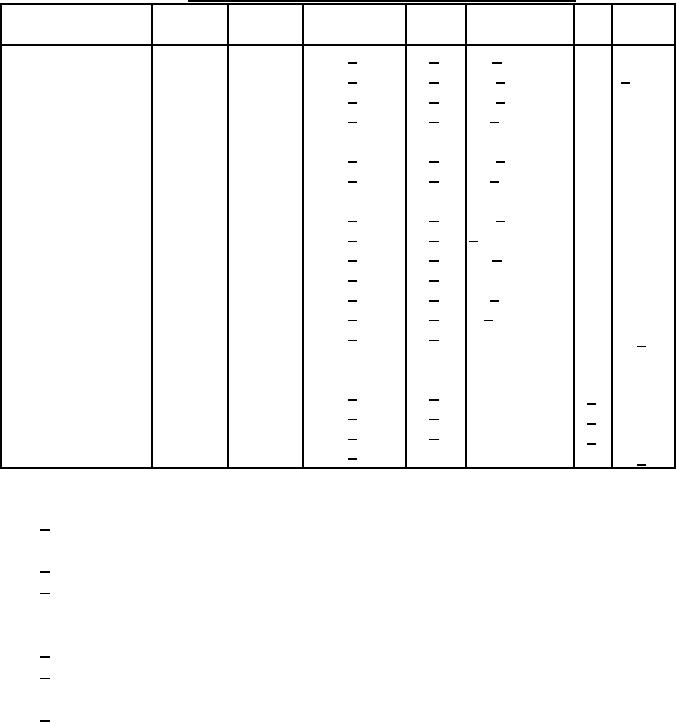

TABLE III. Classification of inspection and frequencies (bushings).

Require-

First

In-process

Control

Title

ment

Inspection Qualification

article

inspection

CI

test

Specific gravity

3.3.3.2

4.7.1.1

1/

1/

1/ Batch

Hardness

3.3.3.3

4.7.1.2

1/

1/

1/ Shift

1/Shift

Tensile strength

3.3.3.4

4.7.1.3

1/

1/

1/ Shift

Tensile strength

3.3.3.5

4.7.1.4

1/

1/

1/ Month

(aged)

Ultimate elongation

3.3.3.4

4.7.1.5

1/

1/

1/ Shift

Ultimate elongation

3.3.3.5

4.7.1.6

1/

1/

1/ Month

(aged)

Tensile stress

3.3.3.4

4.7.1.7

1/

1/

1/ Shift

TGA

3.3.3.6

4.7.1.8

1/

1/

1/ Bi-Monthly

Cure meter

3.3.3.7

1/

1/ Batch

4.7.1.9

1/

Adhesion

3.3.3.8

1/

1/

4.7.1.10

1/Shift

Compression set

3.3.3.9

1/

1/

1/ Month

4.7.1.11

1/

1/

1/ Monthly

Brittleness

3.3.3.10

4.7.1.12

GC mass spec

3.3.3.11

1/

1/

4.7.1.13

4/

Bushing fill

1/Mold

1/Mold

3.5.4

4.7.1.14

1/New

Mold

Concentricity

2/

2/

3.5.4.1

4.7.1.15

2/

2/

2/

Workmanship

3.5.2

4.5.3.1

2/

Product marking

2/

2/

3.3.4.13

4.5.3.1

2/

Endurance

1/

3.4.1

4.3.3

3/

NOTES:

1/ Samples shall be taken as specified in section 3. Unless otherwise specified (see 6.2),

sample size shall be one.

2/ Sample size shall be in accordance with table V.

3/ Bushing endurance shall be run as specified by the Procuring Activity. During the

course of any given contract, no more than three (3) tests shall be required.

Requirements and sample size shall be in accordance with 3.4.1.

4/ The Government may require samples as specified in 3.3.3.11.

5/ One batch is identified as a full mixer of rubber compound. 1/batch indicates one

sample per batch. 1/bi-monthly indicates one sample every other month.

6/ Samples shall be selected at the location specified in 4.3.1.1 and 4.3.1.2. For

in-process tests, samples are picked right after or while batches are being finalized.

Control Tests would normally be performed on finished bushings (vulcanized).

20

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business