MIL-DTL-11891G(AT)

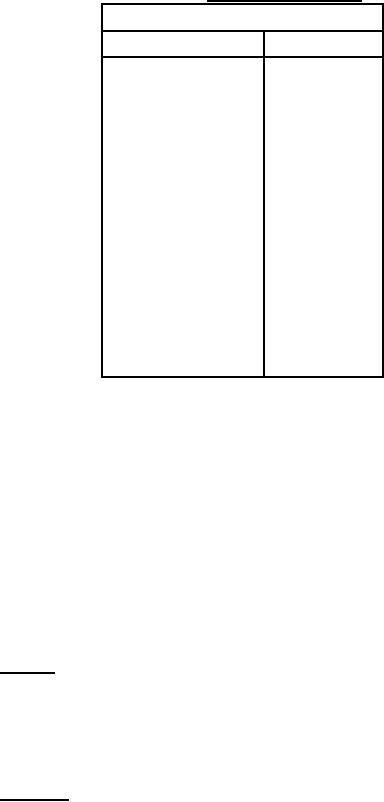

TABLE V. Sampling plan for CI.

CI sampling plan**

Inspection lot size

Sample size

2 to 8

*

9 to 15

13

16 to 25

13

26 to 50

13

51 to 90

13

91 to 150

13

151 to 280

20

1201 to 3200

29

3201 to 10,000

34

10,000 to 35,000

42

35,000 to 150,000

50

150,000 to 500,000

60

500,001 and over

74

90

102

* Indicates entire lot must be inspected (100% inspection).

** Acceptance number is always zero

NOTES:

1. Tightened inspection shall be introduced as soon as 2 out of 5 successive lots have

been rejected and shall, as a minimum, impose a 30 percent increase in sample size.

Normal inspection sampling may be restored after 5 successive lots have been

accepted under tightened inspection.

2. Reduced inspection may be introduced when 10 successive lots have been

accepted and shall as a maximum, permit a 30 percent decrease in sample size.

Normal inspection sampling shall be restored if a lot is not accepted under reduced

inspection.

4.5.3.2 Defects The sample selected in 4.5.3.1 shall be inspected to the requirements of

table IV for roadwheel path and ground pads and table III for bushings. The defects shall be

classified as specified in table VI. Note that table VI addresses only the visual and physical

measurement inspections of vulcanized components. It does not address defects or failures found

upon testing.

4.5.3.3 CI failure. Any item that fails to conform to any specified requirement shall be

rejected and any failure (one or more) of the selected sample or test for the appropriate inspection

lot size shall constitute a failure of the entire lot. The rejected item(s) may be repaired or

corrected and resubmitted for inspection. If the contractor utilizes sampling inspection as an

27

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business